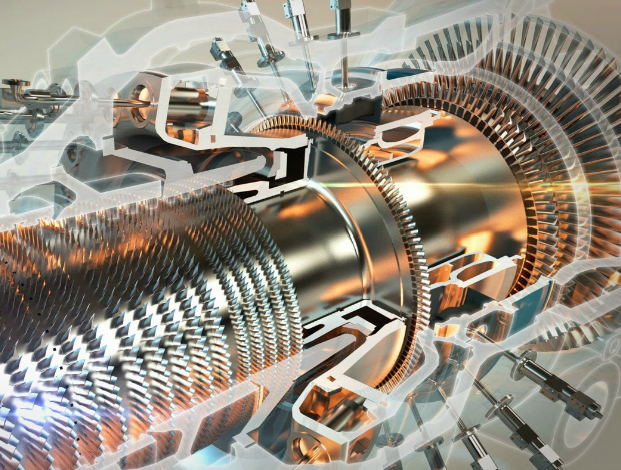

BASIC ROTATING EQUIPMENT: OPERATION, MAINTENANCE & TROUBLESHOOTING

Rotating equipment like turbines, compressors, turboexpanders etc are very important equipment to any process plants. Normally, there are a lot of machinery problems associate to these equipment such as misalignment unbalance, fluid induces instability etc which will interrupt the smooth running and effect its efficiency, thus interrupting the production of the plant. There are various established techniques to troubleshoot this machinery problems which are accepted and established internationally and understanding and mastering such knowledge and skills will be of extreme benefits to the operating plants in ensuring a continuous flow of production by minimizing downtime upon knowing the actual problems of the respective machines. Hence, The Rotating Equipment Engineer (REE) needs to know how to solve the problem and ensure that all new and existing rotating equipment installations are completed in accordance with applicable standards, and support repairs/upgrades to rotating equipment. They also need to know how to prevent equipment defects. For you who want to explore more about Rotating Equipment Maintenance & Troubleshoting theory and field practice, you should participate in this course.

WHO SHOULD ATTEND?

- Engineers of all disciplines

- Managers

- Technicians

- Maintenance personnel

- Other technical individuals

WHAT WILL YOU LEARN?

This 3 days training- will provide a comprehensive understanding of the various types of rotating equipment including centrifugal pumps, centrifugal and axial compressors, and motors. This course will focus on maximizing the efficiency, reliability, and longevity of this equipment by providing an understanding of the characteristics, selection criteria, common problems and repair techniques, preventive and predictive maintenance.

BASIC ROTATING EQUIPMENT COURSE CONTENT

1. Basic Pompa Sentrifugal

2. Basic Rotating Equipment

3. Fundamental Gas Compressor

4. Gas Turbine Principles

5. Mechanical Alignment

6. Laser Alignment

7. Vibration Monitoring

Jadwal Pelatihan Jakarta Training 2023 :

Batch 1 : 03 – 04 Januari 2024 | 16 – 17 Januari 2024 || Batch 2 : 06 – 07 Februari 2024 | 20 – 21 Februari 2024

Batch 2 : 4 – 6 April 2023

Batch 3 : 26 – 28 Juni 2023

Batch 4 : 14 – 16 Agustus 2023

Batch 5 : 10 – 12 Oktober 2023

Batch 6 : 5 – 7 Desember 2023

–

Catatan: Jadwal tersebut dapat disesuaikan dengan kebutuhan calon peserta.Training Afe Budget Migas Jakarta Fixed Running

Biaya dan Lokasi Pelatihan : Pelatihan Estimasi Biaya Proyek Afe Di Jakarta

Training Efe Project Pasti Jalan

- Yogyakarta, Hotel Dafam Malioboro

- Jakarta, Hotel Amaris Tendean

- Bandung, Hotel Golden Flower

- Bali, Hotel Ibis Kuta

Catatan :Biaya diatas belum termasuk akomodasi/penginapan.Training Estimasi Biaya Proyek Afe Jakarta Pasti Running

Investasi Pelatihan Jakarta Training: Pelatihan Efe Project Di Jakarta

- Investasi pelatihan selama tiga hari tersebut menyesuaikan dengan jumlah peserta (on call). *Please feel free to contact us.

- Apabila perusahaan membutuhkan paket in house training, anggaran investasi pelatihan dapat menyesuaikan dengan anggaran perusahaan.

Fasilitas Pelatihan di Jakarta Training: Training Afe Budget Preparation Skills Of Oil & Gas Projects Di Jakarta Murah

-

- Hotel

- Module / Handout

- FREE Flashdisk

- Sertifikat

- FREE Bag or bagpackers (Tas Training)

- Training Kit (Dokumentasi photo, Blocknote, ATK, etc)

- 2xCoffe Break & 1 Lunch, Dinner

- FREE Souvenir Exclusive

- Training room full AC and Multimedia

Technorati Tags: training afe budget preparation skills of oil & gas projects di jakarta,training afe budget migas di jakarta,training estimasi biaya proyek afe di jakarta,training efe project di jakarta,pelatihan afe budget preparation skills of oil & gas projects di jakarta